Hidden Product Residues vs. Chematic Science-With-Cleaning: Personal Care Edition

An ineffective cleaning process can lead to increased downtime, lost earnings, product impurities and multiple safety concerns. Chematic’s proven Science-With-Cleaning strategy combines the right detergent targeted for your specific residue with the appropriate cleaning process to optimize your cleaning efforts.

The first step to formulating a cleaning process that is best for your personal care manufacturing equipment is to KNOW YOUR RESIDUE!

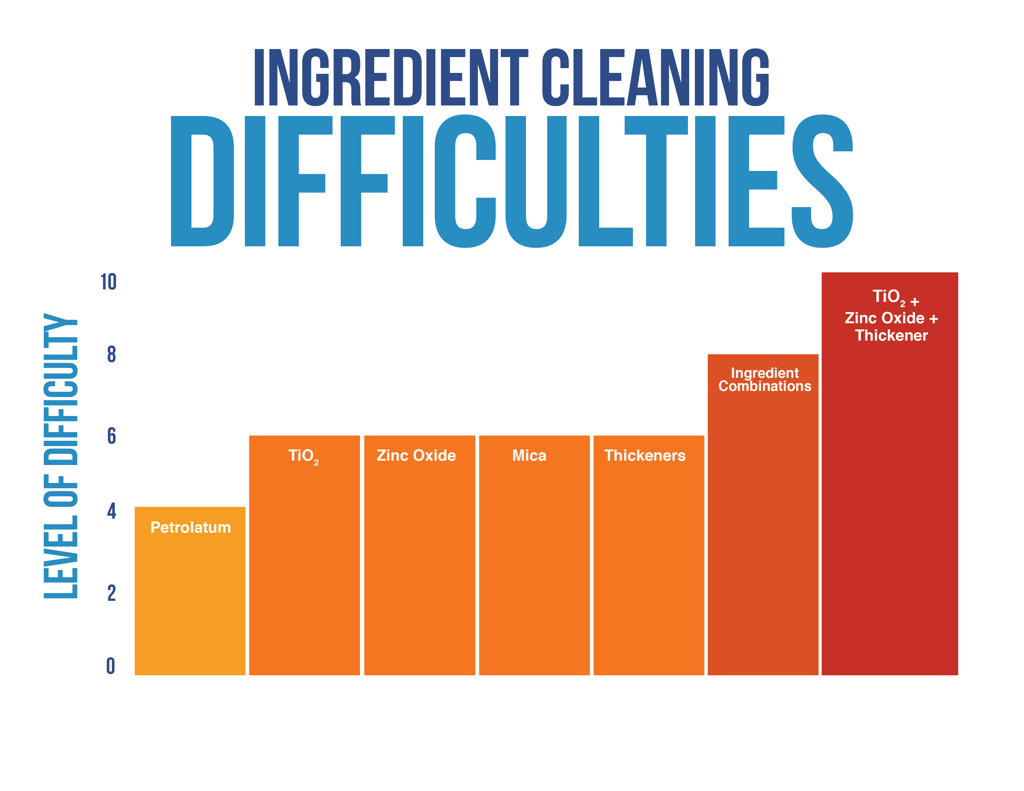

The components found in the formulations of personal care products (i.e. sunscreen, lotions, ointments, creams, pastes, and makeup) leave manufacturing equipment more difficult to clean. Product residues and hazes left behind on equipment after cleaning with a traditional highly alkaline detergent, or the wrong process, impacts product integrity and equipment efficiency.

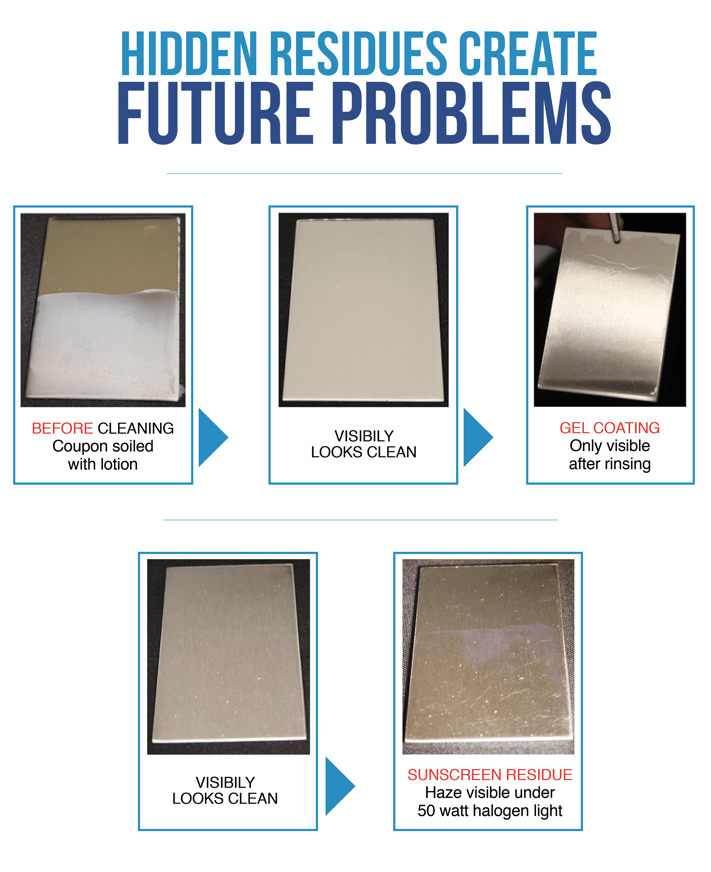

Maybe your personal care manufacturing line has faced the classic dilemma of ‘hidden product residue’ during the cleaning process; when you think your equipment is clean but from another angle or in different lighting your can see that that’s not the case.

First and foremost, this left-on residue can compromise your product if not recognized and eliminated. In the best-case scenario, hidden residue is recognized then the equipment re-cleaned until the remaining residue is removed. This inefficient cleaning process uses more cleaning materials, increases equipment downtime and labor hours, and possibly causes a delay in production capacity. Check ourHow to Clean Titanium Dioxide guide to learn more about hidden hazes and best practices.

First and foremost, this left-on residue can compromise your product if not recognized and eliminated. In the best-case scenario, hidden residue is recognized then the equipment re-cleaned until the remaining residue is removed. This inefficient cleaning process uses more cleaning materials, increases equipment downtime and labor hours, and possibly causes a delay in production capacity. Check ourHow to Clean Titanium Dioxide guide to learn more about hidden hazes and best practices.

Why not get it right the first time?

Dober labs specialize in recommending formulated detergents, which target tough-to-clean residues, and combine them with a customized cleaning process specifically designed for your manufacturing goals. Our cleaning process targets and eliminates the residues of the personal care manufacturing industry - the first time. As a result we aim to keep your operation running efficiently with decreased downtime, less cleaning material waste, less labor and increased safety.

Ready for Science-With Cleaning? Contact Us or learn more by downloading our Personal Care Cleaning Magazine.