Increased Environmental Performance at Large US Refinery

The Challenge:

A large oil refinery in the US committed to safety, the environment, and continuously improving supplier performance standards was faced with the challenge of increasing environmental performance and cutting costs for coagulant use in their wastewater processing units. This refinery has five different coagulant applications as part of its wastewater processing. In 2013, the refinery was challenged with the following: loss of a process water tank, a drive to improve environmental results at the wastewater treatment plant, and better cost control for the coagulant used throughout the refinery. The coagulant used at the PSO and IGF units was identified as an application where improvements in cost and performance could be made. To achieve this goal, a unique GreenFloc natural coagulant chemistry innovated by Dober’s Water Treatment Division was chosen for the treatment of the PSO and IGF units.

The Solution:

Dober’s GreenFloc natural coagulant product line includes sustainable, effective, and innovative natural coagulants for use across a wide variety of industrial applications. Dober’s Water Treatment Division was challenged to innovate a replacement coagulant for the traditional polyDADMAC/PAC blend that was being used. Dober’s new GreenFloc natural coagulant, GFT 6173, is a result of months of product research and development in our world class laboratories and on-site testing and validation with the customer. The newly formulated product was put to test with a full-scale trial at the refinery.

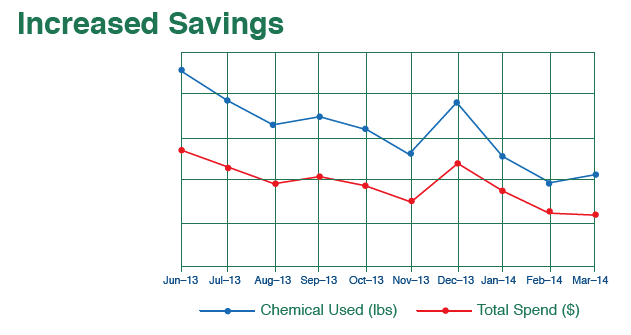

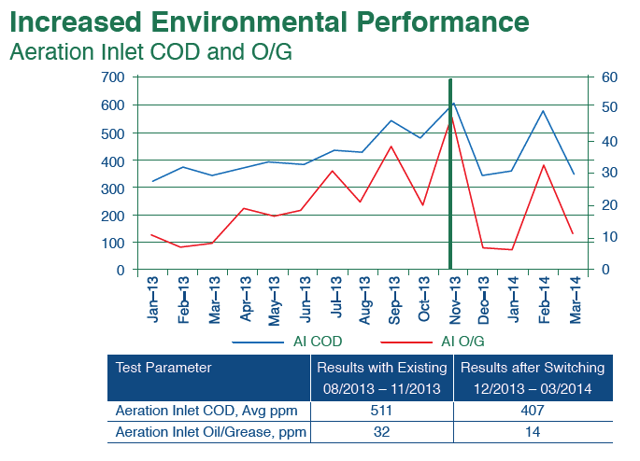

The Results:

Dober’s world class Research Team at our Innovation and Technology Center in Woodridge, Illinois successfully innovated a new environmentally friendly and cost competitive natural coagulant for use at this refinery’s PSO and IGF Units. When put to the test, GFT 6173 successfully exceeded all refinery standards of excellence. GFT 6173 successfully reduced Aeration Inlet COD by 20%, Aeration Inlet Oil/Grease by 44%, and quarterly chemical spend by 18%. These results allowed the new natural coagulant to be put into service full-time and has continued the same great sustainable performance day-in and day-out.